Description

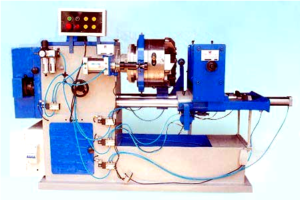

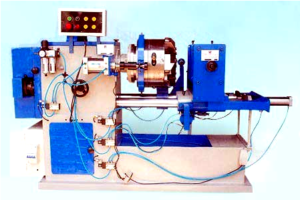

Based on advanced technology, Rebar Threading Machine is a revolutionary machine for threading forged ends of reinforcement bars. Rebar Threading Machine is designed for the precise production of Rebar, reinforcing bar, for concrete foundations. With futuristic design, Rebar Threading Machine significantly reduces effort, thus boosts productivity to a great extent. Rebar Threading Machine offers several other benefits such as low operating cost, easy installation & maintenance, non-corrosivehousing and fast operation that make it worth buying. We are a Manufacturer, Exporter, and Supplier of Rebar Threading Machine, based in Ludhiana, Punjab. For further technical information, please contact us.

Functions of This Machine:

The Threading Machine is used for Cutting External Thread on Components by Chasing method. HSS Tangential Chasers are used as cutters. Component remains stationary and Die Head rotates. Matric, BSP, BSPT, NPT, UNF,UNC, BSW, Acme Threads, B.S.F etc. threads can be cut on this machine depending upon the type of Chasers.

Send Inquiry:- sales@nationalcuttingtools.com

Technical Specifications

|

Capacity |

Model NCT-1.1/2″ |

Model NCT-2.1/2″ |

|

Saddle Movement |

12″-14″ |

14″ – 16″ |

|

Spindle Speed Range |

60-90 |

60-90 |

|

Number of Spindle Speed |

2 |

2 |

|

Threading Capacity |

3/8″ to 1.1/2″ |

1/2″ to 2.1/2″ |

|

Production per Hour |

60-80 |

60-80 |

|

H.P. Required |

3 H.P. 960 RPM |

7.5 H.P. 960 RPM |

|

Lead Screw |

N.A |

N.A |

|

Weight (KG) |

550 |

990 |

Rebar Threading Machine comprises of a Base, Head Shock, Saddle, Bed Type Clamping Vice and Die Head. During the cutting process, Die Head rotates and the bar remains stationary. This machine can be used for cutting a wide range of threads that include Matric, BSP, BSPT, NPT, UNF, BSW, Acme Threads, etc.

Reviews

There are no reviews yet.