Description

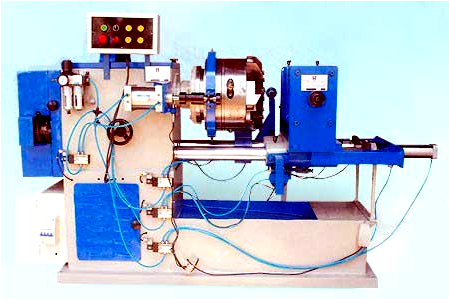

National Cutting Tools is a distinguished Manufacturer, Exporter and Supplier of Pipe Threading Machine in India. By offering three types of Pipe Threading Machine namely conduit pipe threading mac, PVC pipe threading machine and Steel Pipe Threading Machine, we are ruling domestic as well as international trade channel. Factors like excellent performance, minimal maintenance, and easy installation convey a lot to the preference of our Pipe Threading Machine.

Design & Workmanship : The Nationwide Reducing Tools thread cutting machines are developed to generate great quality threads within the tolerance for which they were developed.

Head Stock : A higher great quality designed Go Box is of best great quality launching offering support to the spindle bearings. The box is of equipment type, oiled, fixed with three additional great high quality bearings.

The Bed : The bed is pillar type having two support beams created of best great quality metal perfectly finished & properly difficult firefox coated in the most modern difficult firefox plating unit.

The Saddle : The Seat is fixed on two pillars very precisely. It operates on support beams very efficiently and perfectly to the Go Inventory positioning.

The Apron : The attire gives activity to the saddle with head exchange along with support beams through metal holder and pinion preparations. It’s all equipment are created of best great quality metal.

Vice Jaws : The vice oral cavity created from the best great quality metal are fixed on the saddle well arranged with the top stock center fixed in a great high quality box type vice. The oral cavity is warm handled. The motions of oral cavity are managed by the saddle.

Range

-

1/4″ to 1″ do/-

-

3/8″ to 1.12″ do/-

-

1/2″ to 2.1/2″ do/-

-

1″ to 4″ Capacity Pipe

-

2.1/2″ to 6″ Capacity Pipe

-

4″ to 8″ 4″ to 8″ Capacity Pipe

Send Inquiry:- sales@nationalcuttingtools.com

Functions of This Machine:

The Threading Machine is used for Cutting External Thread on Components by Chasing method. HSS Tangential Chasers are used as cutters. Component remains stationary and Die Head rotates. Matric, BSP, BSPT, NPT, UNF,UNC, BSW, Acme Threads, B.S.F etc. threads can be cut on this machine depending upon the type of Chasers.

| Model NCT-1″ | 1/4″ to 1″ |

| Saddle Movement | 10″ |

| Spindle Speed Range | 60-90 |

| Number of Spindle Speed | 2 |

| Threading Capacity | 1/4″ to 1″ |

| Production per Hour | 60-80 |

| H.P. Required | 3 H.P. 960 RPM |

| Lead Screw | NIL |

| Weight (KG) | 500 |

| Model NCT-1.1/2″ | 3/8″” to 1.1/2″ |

| Saddle Movement | 10″-12″ |

| Spindle Speed Range | 60-90 |

| Number of Spindle Speed | 2 |

| Threading Capacity | 3/8″ to 1.1/2″ |

| Production per Hour | 60-80 |

| H.P. Required | 3 H.P. 960 RPM |

| Lead Screw | NIL |

| Weight (KG) | 550 |

| Model NCT-2.1/2″ | 1/2″ to 2.1/2″ (Bed Type) | 1/2″ to 2.1/2(PillarType) |

| Saddle Movement | 14″-16″ | 12″-16″ |

| Spindle Speed Range | 60-90 | 60-90-120 |

| Number of Spindle Speed | 2 | 3 |

| Threading Capacity | 1/2″ to 2.1/2″ | 1/2″ to 2.1/2″ |

| Production per Hour | 60-80 | 70-90 |

| H.P. Required | 7.5 H.P. 960 RPM | 7.5 H.P. 960 RPM |

| Lead Screw | As Per Requirement | As Per Requirement |

| Weight (KG) | Weight (KG) | 990 |

| Model NCT-4″ | 1″ to 4″ (Pillar Type) |

| Saddle Movement | 10″-12″ |

| Spindle Speed Range | 40-75-115 |

| Number of Spindl Speed | 3 |

| Threading Capacity | 1″ to 4″ |

| Production per Hour | 35-40 |

| H.P. Required | 12.5 H.P. 960 RPM |

| Lead Screw | Provided |

| Weight (KG) | 1600 |

| Model NCT-6″ | 2.1/2″ to 6″(Pillar Type) |

| Saddle Movement | 10″-12″ |

| Spindle Speed Range | 25-50 |

| Number of Spindle Speed | 2 |

| Threading Capacity | 2.1/2″ to 6″ |

| Production per Hour | 20-25 |

| H.P. Required | 15 H.P. 960 RPM |

| Lead Screw | Provided |

| Weight (KG) | 1900 |

| Model NCT-8″ | 4″ to 8″ (Pillar Type) |

| Saddle Movement | 10″-12″ |

| Spindle Speed Range | 25-50 |

| Number of SpindlSpeed | 2 |

| Threading Capacity | 4″ to 8″ |

| Production per Hour | 15-20 |

| H.P. Required | 20 H.P. 960 RPM |

| Lead Screw | Provided |

| Weight (KG) | 2500 |

Reviews

There are no reviews yet.